|

Engineering services

At the

request of the customer is performed design, development and manufacture of

hydraulic oil stations, hydraulic drives and hydraulic power units for various

purposes, their commissioning and adjusting.

|

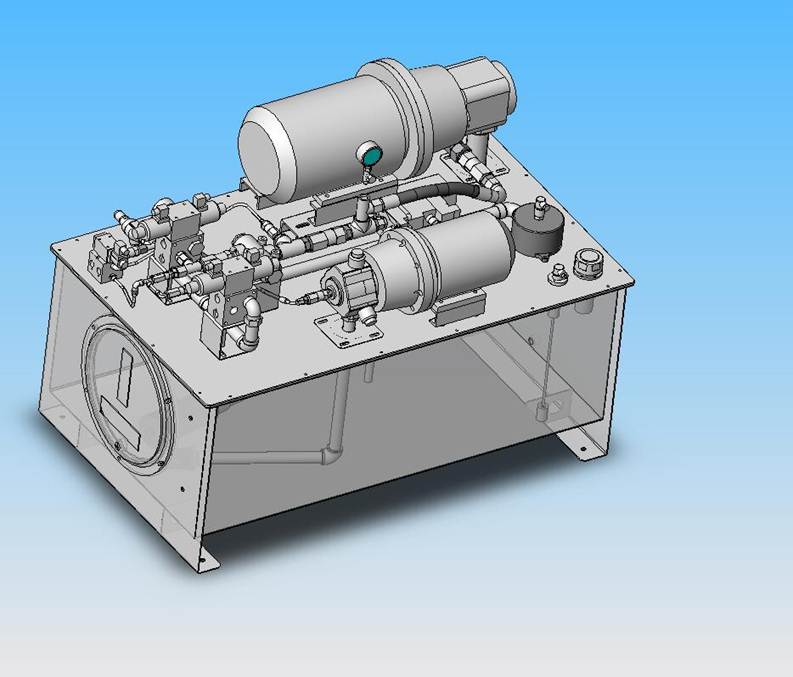

In

the process of designing of the hydraulic unit, our engineers create 3-D

model of the future product. This helps to avoid possible errors, create an

optimal layout of the installation, easy operation and maintenance, with

minimum weight and dimensions. And, of course, lower costs, even before the

start of production.

|

|

An example of manufacturing

of the hydraulic system.

|

On order, the

company provides design and manufacture of hydraulic oil stations, hydraulic

drives and hydraulic power units for various purposes, their commissioning

and adjusting.

|

|

Developing and implementing a system for hydraulic

filter press KMPm-196.

In 2008, under order of Machine-Building

Plant "Progress", Ukraine, "Meta" company developed hydraulic

system that ensure work of the filter press KMPm-196.

|

|

The entire

hydraulic system on the basis of "MP Filtri" and "ATOS"

elements was developed and manufactured by the company "Meta".

The process of working on creation of the

hydraulic system consisted of the following steps:

·

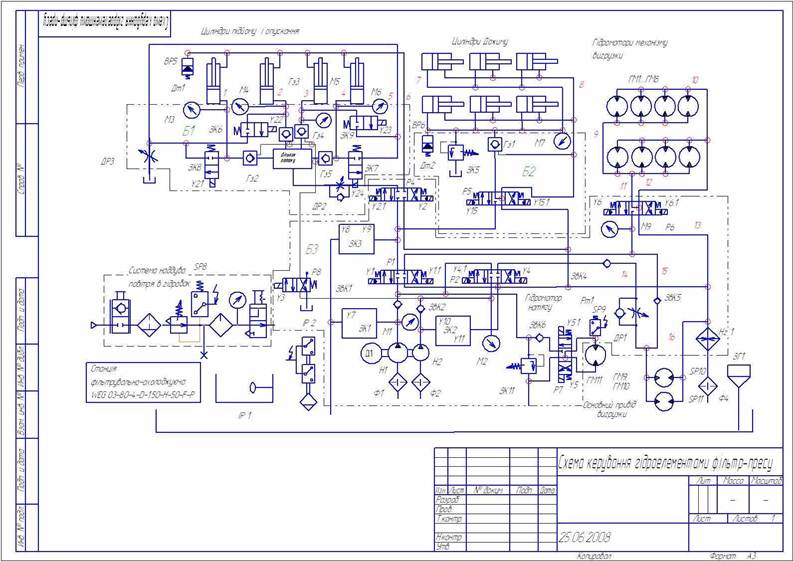

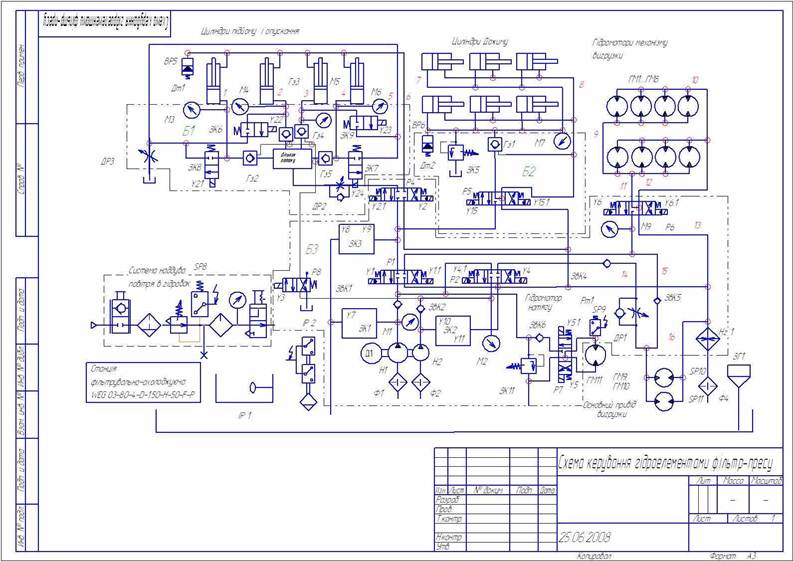

Developing of the hydraulic diagram. By order

of the customer, was developed the hydraulic diagram of press, that provides

synchronous operation of filter plates, broach of filter filter fabric feeding of the slurry, the

operation of all nodes of the filter press.

|

|

|

|

·

After reviewing and approval of the hydraulic

diagram by the customer, the design documentation is made: drawings and 3-D

model of hydrostation.

|

|

|

|

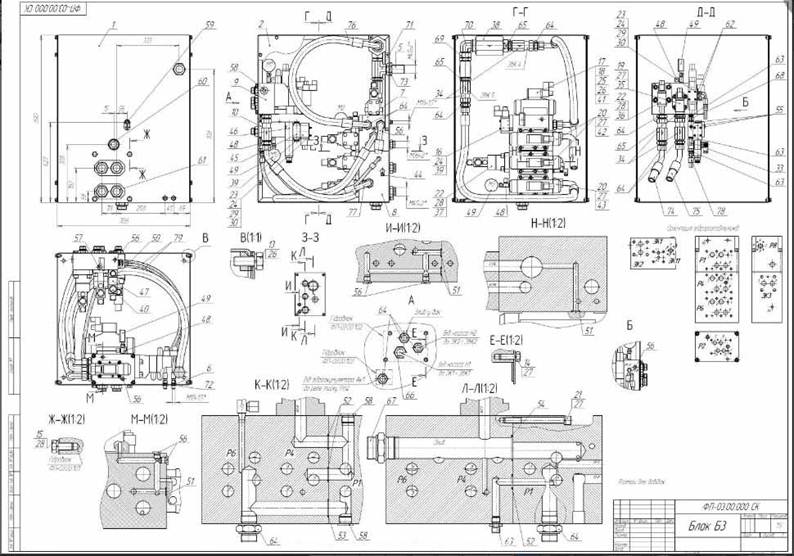

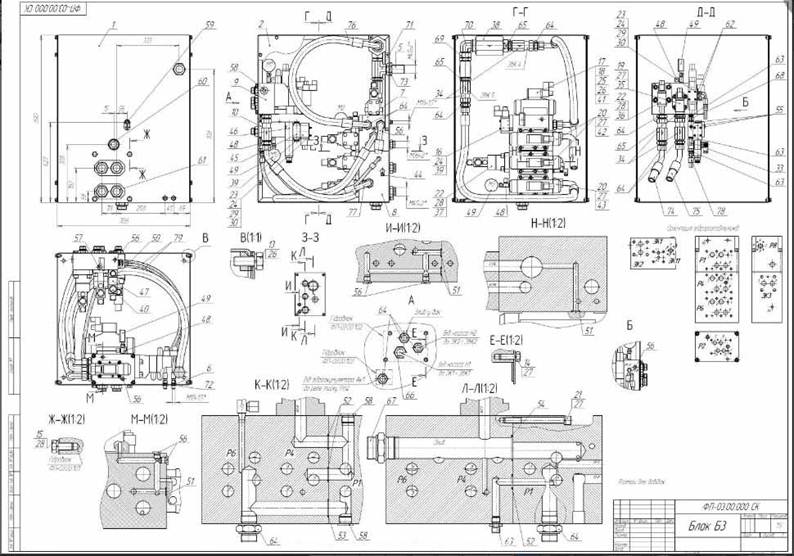

·

Project of the control unit for hydraulic

cylinders is represented on the drawing

|

|

The filter

press is designed to enrich the ore and to get concentrate. Enriching of ore

occurs by dissolving the ore with water, after which the resulting slurry is

fed through a pipeline system to a filter press, where, after squeezing, the

water and burden is removed. In result, the ore concentrate is getting.

Filtering process is taking place in the press KMPm-196. This is a modern

machine that allows getting 18 tons of finished concentrate for one cycle,

which lasts several minutes.

The height of the filter press is 9,6 m,

total weight - 75 tons

weight of the filter plates - 16 tons

productivity per shift - 1,400 tons of

ore concentrate.

|

|

|

|

|

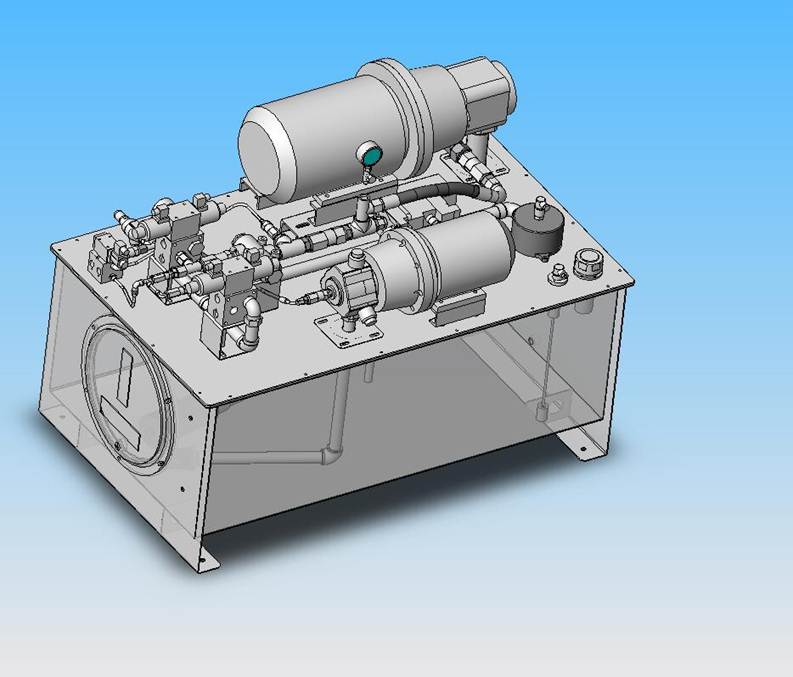

Lifting of

filters battery provides the hydraulic power unit, actuated by 75 kW electric

motor. The entire workflow is provided by hydraulic system, which controls the

computer in automatic mode.

|

|

|